Automotive

Your trusted partner for custom automotive components

RPK Group is an experienced and reputable supplier of innovative components for the automotive industry. They are the core of our business. We are building long-term relationships with the top drivers of the segment as Tier 1 vendors and OEMs; our top 10 customers have been closely linked to us for more than 45 years. Our engineering teams, located in Europe, North America, and Asia, work closely with their engineers right from the start of the project, providing local-to-local custom solutions for our global customers.

Spring and stamping and bending applications in the automotive industry

Springs and metal solutions for the automotive industry

Get the most out of our expertise in the automotive industry

Our engineers work alongside our customers to find the best solution for them, applying scientific methods and knowledge accumulated over almost 50 years.

Related news

RPK Group Showcases High-Value Automotive Solutions at Auto Components Show 2025 India

Visit us at Booth #B48 in Chennai to explore advanced springs and metal-formed components for powertrain, brakes, chassis, eMobility, and more

Read more

Canted coil springs: precision, reliability, and performance

Beveled contact springs are essential components that ensure reliable electrical and mechanical connections in demanding environments. Their design, featuring inclined coils and flattened edges, enhances conductivity, sealing, and durability.

Read more

Flat washers or rings: functionality and precision for your Assemblies

Flat washers are key components in mechanical assemblies, distributing load, preventing damage, and ensuring precise alignment. Though they may seem simple, choosing the wrong one can lead to failures.

Read more

Case Study: High-Reliability Silver Contact Spring for Integrated Brake Control (IBC)

Precision manufacturing for critical braking applications

Read more

RPK India Receives A+ Grade for Excellence from Gabriel India

Recognized for Outstanding Quality and On-Time Delivery

Read more

Case Study: Engineering and Industrialization of Optimized Contact Spring Design for Automotive Lighting

RPK Group integrates FEM/FEA analysis, advanced materials, high-precision tooling, and cleanroom technology to optimize the performance and integration of contact springs in automotive PCB assemblies.

Read more

Flexible Bus Bars: The Efficient Solution for Power Transmission

It optimizes power distribution by offering efficiency, reduced heat, and space savings—ideal for electric vehicles and renewable energy.

Read more

Case study: strengthen wave spring performance with CuBe material

Enhancing reliability and electrical conductivity with innovative material solutions and precision engineering

Read more

Enhancing the Welding of Flexible Copper Busbars with BrightLine Laser Technology

RPK Group incorporates TRUMPF's precision laser welding for efficient, high-quality results in electric vehicle power systems and many other applications

Read more

Enhance your application’s performance with Bus Bar prototyping

Creating the perfect bus bar: from engineering and prototyping to serial production.

Read more

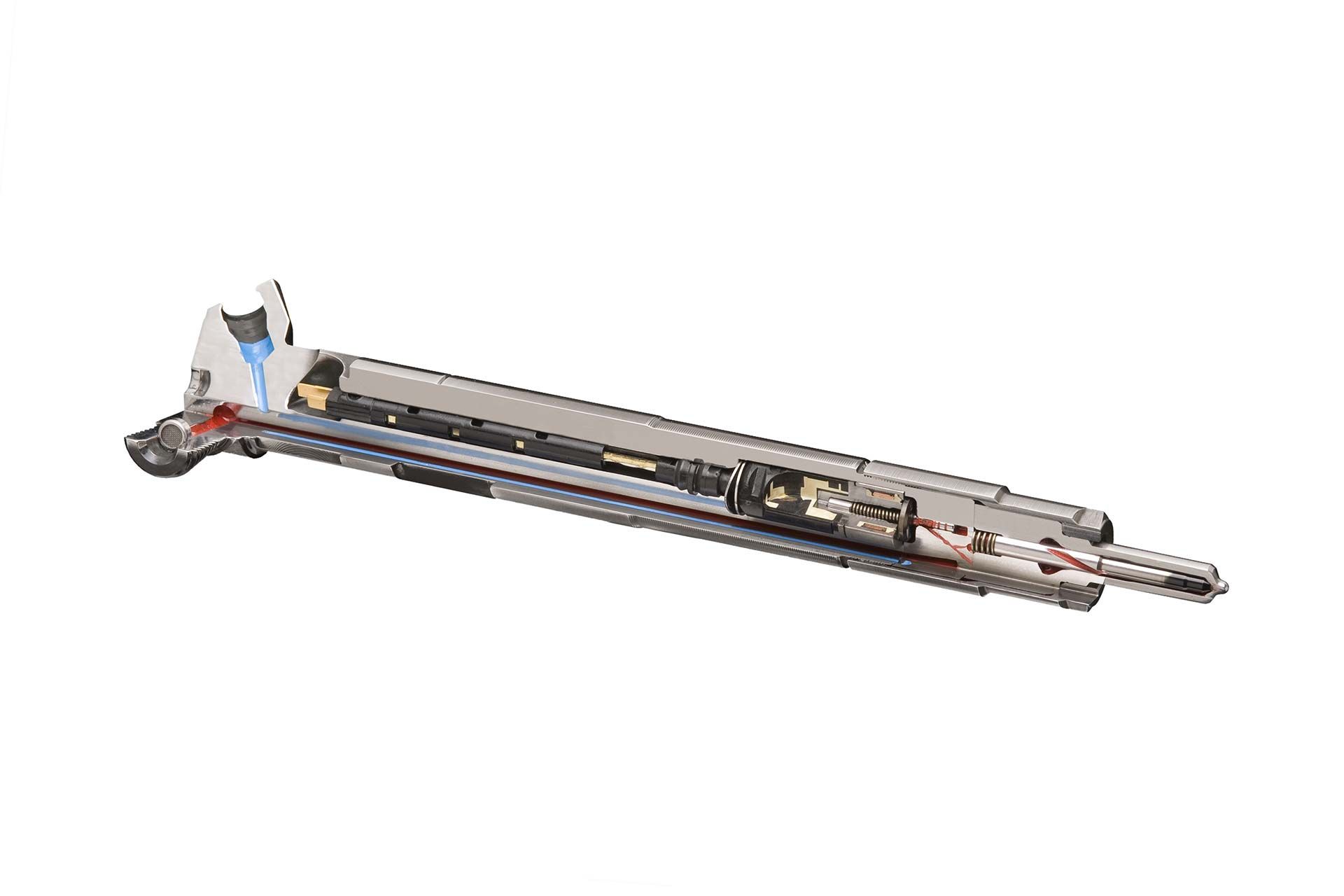

Case Study: Pedal Travel Sensor for Braking System to optimize the precision

Collaborating with the Customer and brainstorming to come up with a solution together to integrate a sensor into a brake pedal.

Read more

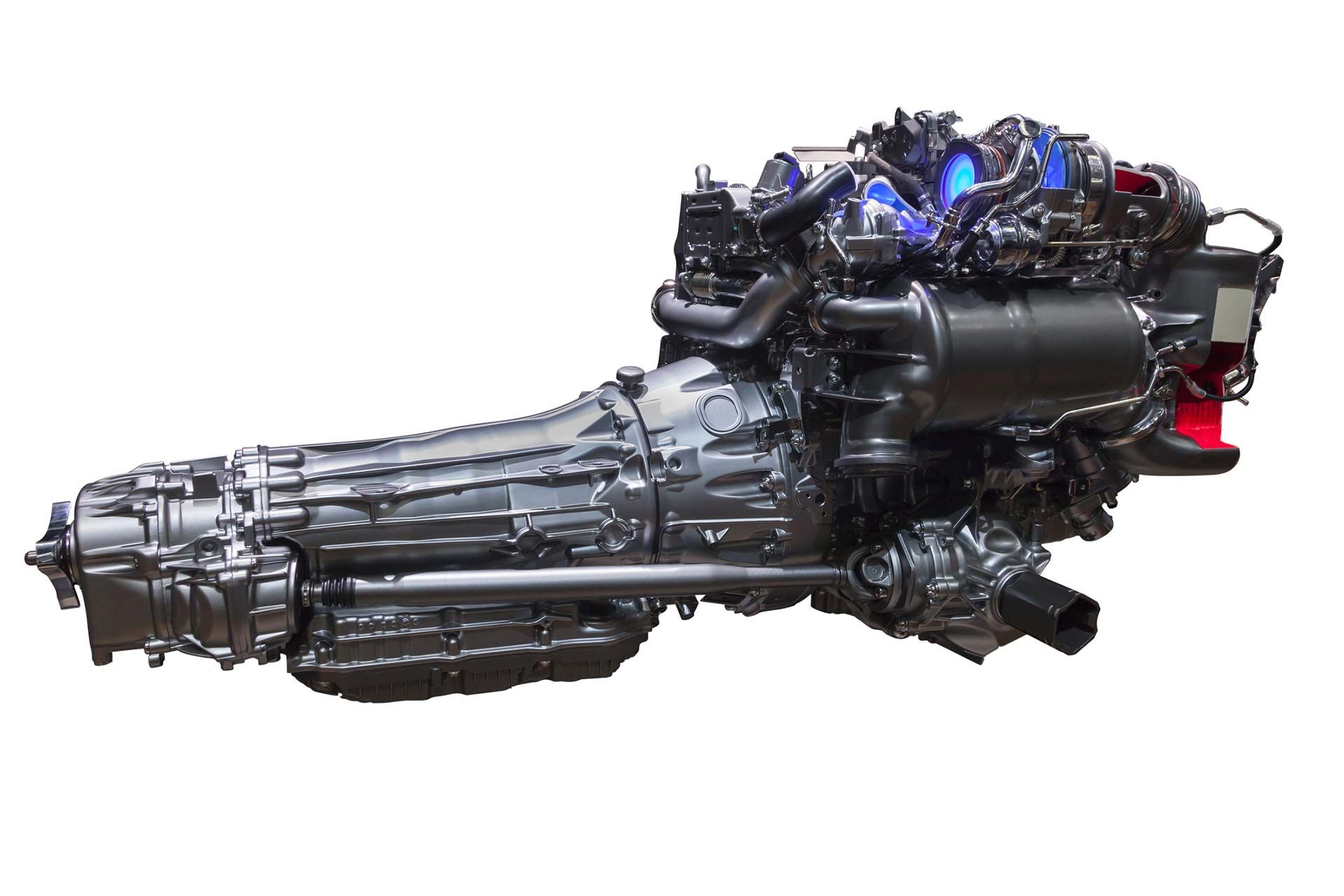

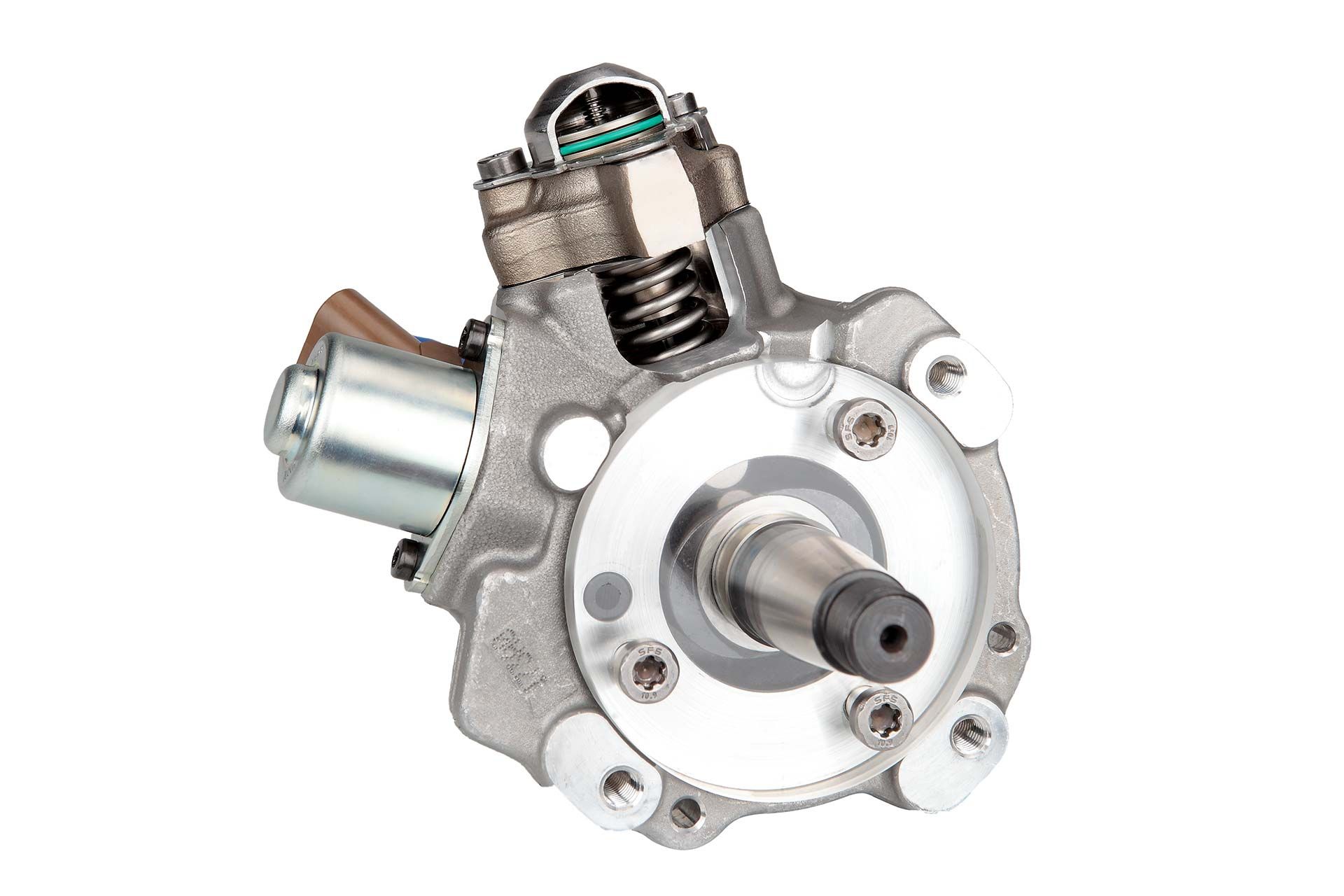

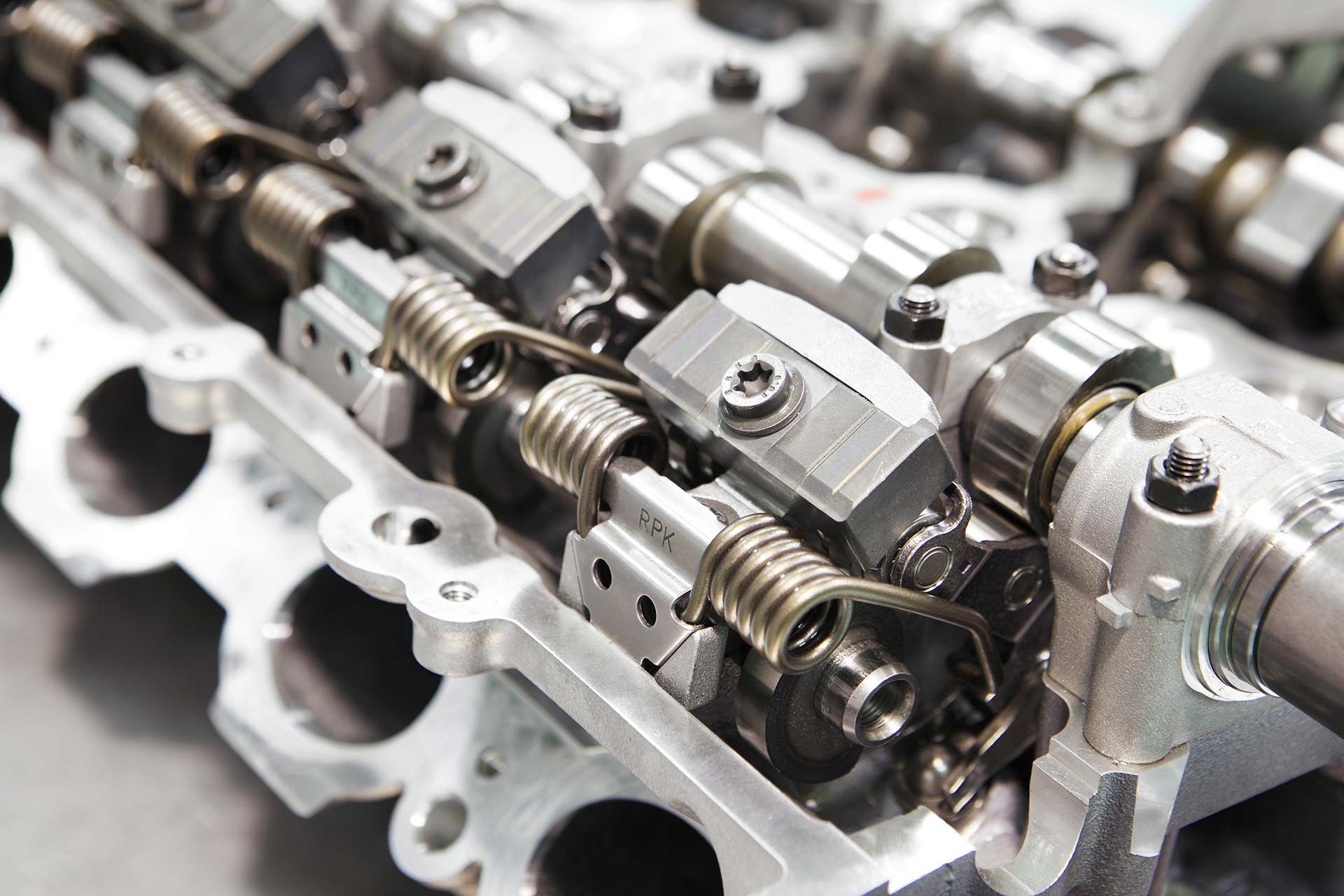

Spring Solutions for Powertrain by RPK Group

Over 50 Years of Excellence in Designing and Manufacturing Springs and Metal Components for the Powertrain

Read more

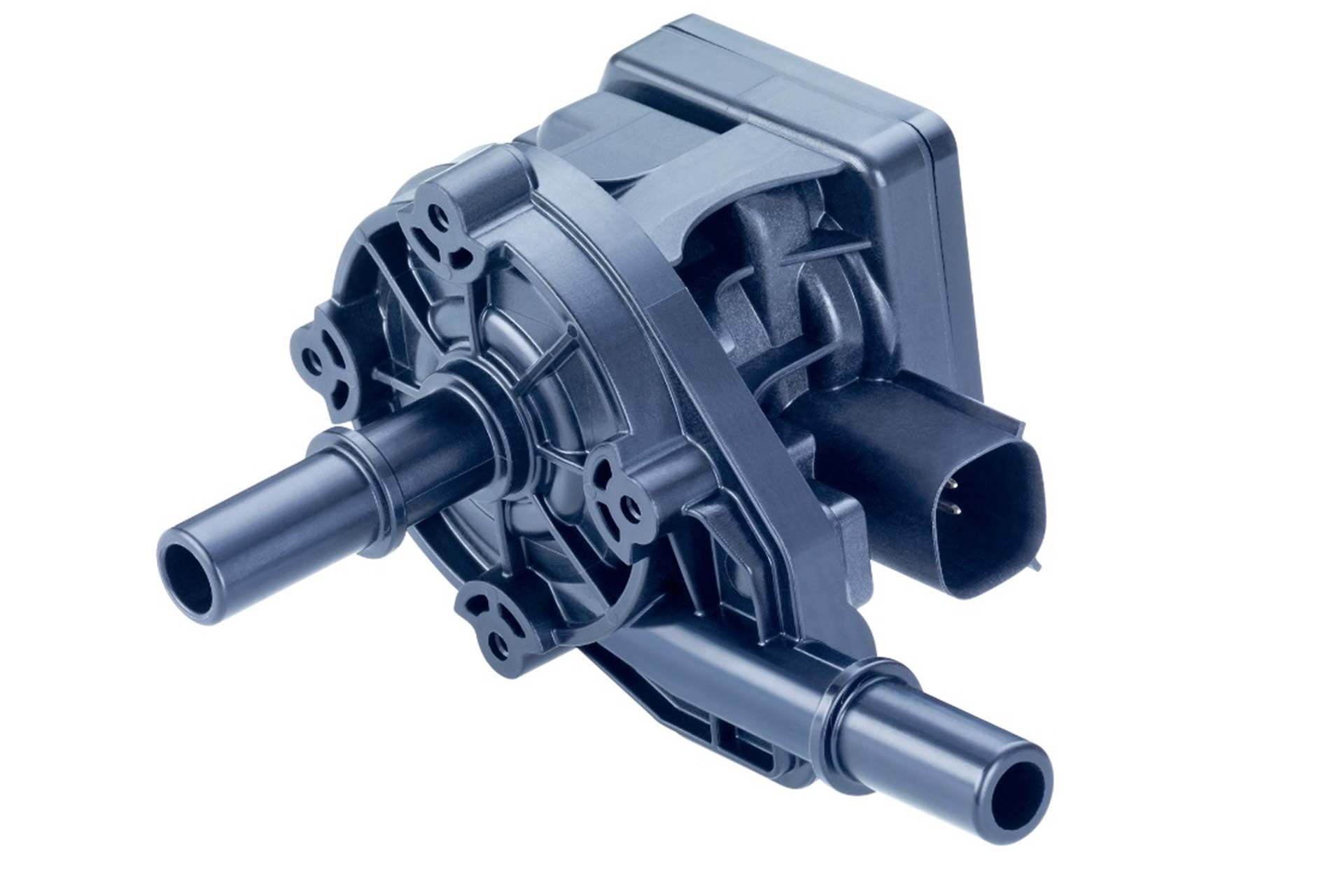

Revolutionizing Automotive Engineering: RPK Group's Cutting-Edge Solutions for EV

Pioneering Prototyping and manufacturing for Electric, Hybrid, and Hydrogen Vehicles

Read more

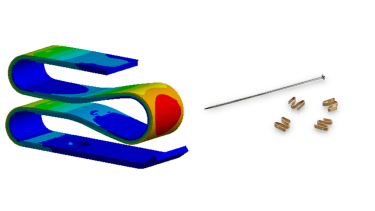

Case Study: Custom Canted/Slant Coil Springs, Precision Engineering Solutions

Combining helicoidal compression springs and welding expertise for optimal power management and mechanical retention.

Read more

RPK Group: pioneering dynamic parts for the automotive industry

From bending to stamping: customized solutions with global reach

Read more

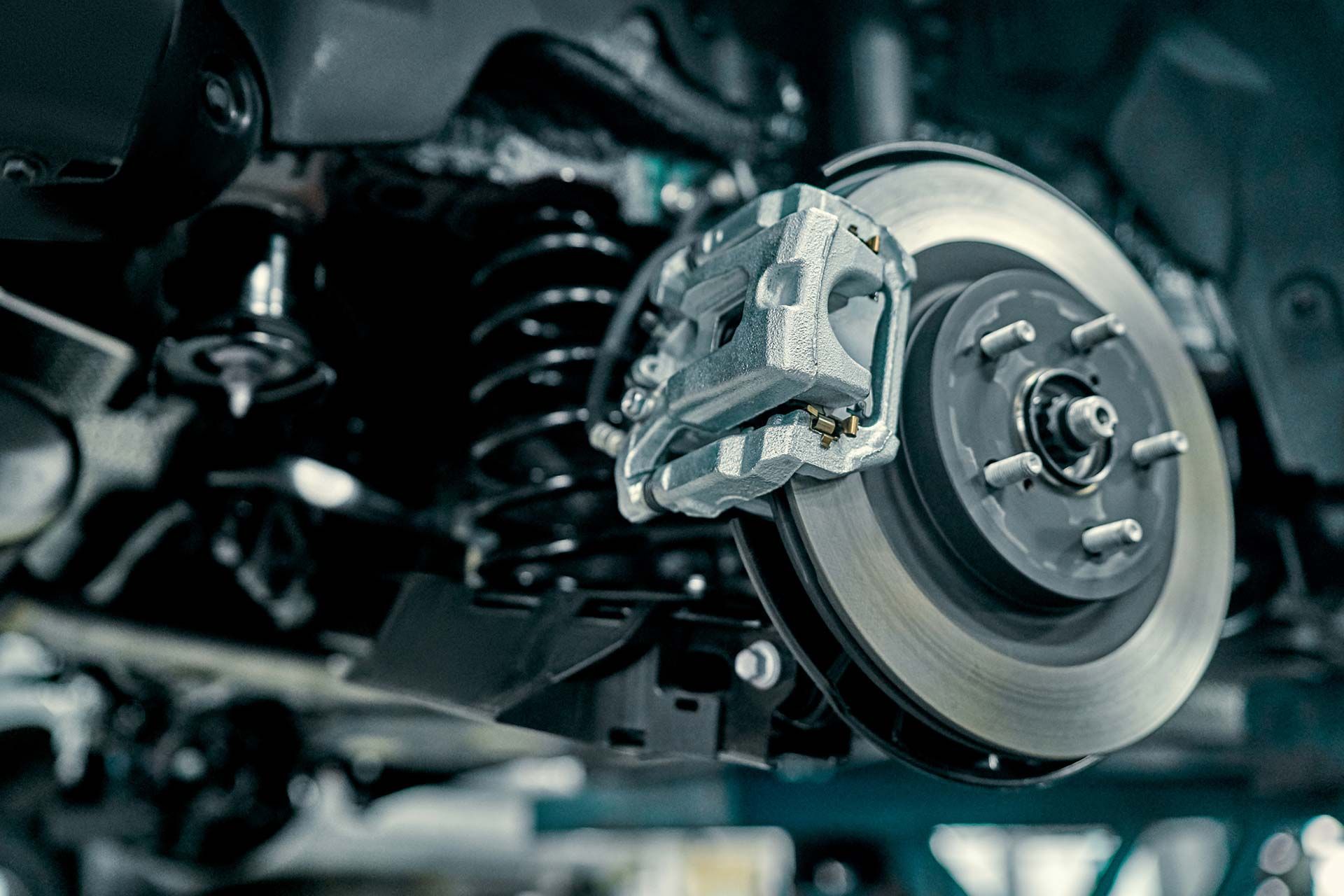

Case study: Quad Clip Challenge, a reverse engineering success in brake system innovation

Discover the exceptional skill of RPK Group in designing a revolutionary four-function brake solution in free-state mode

Read more

Case Study: Enhancing a Contact Spring for Driving Assistance System with Precision Engineering

From FEM/FEA Analysis to High-Precision Tooling: RPK Group's Comprehensive Approach Delivers Enhanced Performance and Seamless Integration in Radar Technology

Read more

RPK Group, metal components, bus bars, and springs for hydrogen vehicles

Pioneering Hydrogen Solutions for a Sustainable Tomorrow

Read more

Case study: benefits of a Wave Spring vs Compression Coil Spring in a shock absorber valve

Why did we design a wave spring over a compression coil spring to solve issues due to limited space and lateral loads?

Read more

RPK Group Mexico wins GM Supplier Quality Excellence Award

General Motors recognize RPK Group for exceeding the stringent set of quality performance criteria throughout the year

Read more

Celebrating Sustainability: RPK Group receives Schaeffler Supplier Award

RPK Group has been honored with the Schaeffler Supplier Award 2023 for our outstanding commitment to sustainability.

Read more

Wave Springs

Wave Springs

Compression Springs

Compression Springs

Sheet metal bending and stamping

Sheet metal bending and stamping

Tension Springs

Tension Springs

Torsion Spring

Torsion Spring

Spiral Springs

Spiral Springs

Wire forms

Wire forms

Ring and seals

Ring and seals

Arc Springs

Arc Springs