Privacy Policy

Here at RPK, S.COOP.[F-01.009.554] (the “Company”) we are aware of user concerns regarding privacy. This Online Privacy Policy describes the types of personal data obtained through this site, how we use user data and in accordance with which legal terms, who we communicate it to, how long we store the data and the rights and options available to the users of our Site regarding the use made of their personal data. Similarly, we outline the measures taken to protect the security of the personal data gathered and how users can contact us to find out about our methods used concerning privacy.

Person/entity responsible for data processing

The entity responsible for processing personal data (that is the person/entity responsible for data storage) is RPK, S.COOP. [F-01.009.554] [Calle Portal de Gamarra, 34, 01013, Vitoria-Gasteiz (Álava)].

The Site user expressly voluntarily and clearly agrees to the inclusion of all their personal data provided to the Company on the site, e-mail, blogs or social media sites belonging to the Company in files which are both the property and the responsibility of the Company, as well as the processing of all their personal data for the purposes outlined in the following sections of this Online Privacy Policy and which is subject to the terms and conditions set out herein. Our practises regarding privacy may vary in the different countries in which we operate in an aim to reflect local practices and legal requirements.

The data we gather

On our Site we gather certain data including personal data. The types of personal data we may gather may include the following:

- Contact details (such as name, [postal address, email address and telephone number]);

How we use the data we gather and the legal grounds

The data we gather may be used for the following purposes:

- To respond to user enquiries in which case the legal grounds for the data processing are the user’s consent when the moment they make their enquiry;

- To personalise preferences and visits to our Site by our users and provide content adapted to their interests and the way in which they navigate and interact with our Site, in which case the legal grounds for this data processing will be our legitimate interest to improve the services provided on our online Site:

- To operate, evaluate and improve our business (including the development of new products and services; the management, improvement and analysis of our products, services, business and the Site; the management of our communication and the development and other internal functions) in which case the legal grounds for this data processing are our own legitimate interest in improving the services provided on our site; and

- Complying with and requiring compliance with the applicable legal requirements, the respective sector regulations, contractual obligations and our policies, in which case the legal grounds for the data processing will be compliance with the aforementioned legal requirements.

In the event that we use your personal data in a different way to that described above, we will specifically inform you at the time we gather the data.

Data storage

The Company will store the user’s personal data solely for the period necessary to fulfil the purposes for which it was gathered unless you revoke the consent granted. Subsequently, in the event that it is necessary, the information will remain blocked for the legally established periods.

The Information we Share

The personal data of users gathered on this Site may be revealed to third parties solely in accordance with that established in this Online Privacy Notice. The personal data gathered on the Site may be passed on to [companies in the Group?] for administration and internal management purposes. We will also pass on this personal data to logistic services, IT and website development and management providers, and marketing agencies which provide services on our behalf based on our instructions. We do not authorize these service providers to reveal or disseminate the personal data of users except for those uses which are strictly necessary for the provision of the services in our name or to comply with legal requirements. Furthermore, we may reveal personal user data (i) if we are obliged to do so by law or within the framework of a legal procedure, (ii) to security forces or other civil servants requesting this legally, (iii) when we consider that this is necessary or beneficial to prevent physical harm or financial loss or (iv) within the framework of investigation into fraudulent or illegal activities or those presumed to be. We reserve the right to transfer the user’s personal data in the event of the sale or transfer of the whole or part of our company or our assets (including the cases of restructuring, dissolution or liquidation) in accordance with the applicable legislation.

User Rights and Choices

We provide different options regarding the personal data gathered from you on our Site. In order to update these preferences, delete your personal data from our emailing lists or present a request to do so, please contact us in accordance with that outlined in the section titled “How to Contact us” in this Online Privacy Agreement.

To the extent that this is established by the law of your jurisdiction and in the terms set out therein, You may exercise your rights to access, rectify, delete and object to, as well as to limit the data processing and portability, by sending us written correspondence in accordance with that indicated in the section “How to Contact us” in this Online Privacy Notice. To the extent that this is established by law, you may revoke any consent previously granted or object at any time, for legitimate reasons, to the processing of your personal data, by contacting us in accordance with that set out in the Section “How to Contact us” in this Online Privacy Agreement and we will apply your preferences as stated.

Data Transfer

Your personal data gathered on this Site may be transferred for the purposes described above, [] either in the USA or in other countries. These countries may not have the same data protection regulations as the country in which you initially provided your personal data. When we transfer your personal data to other countries, we will protect you in accordance with that established in this Online Privacy Policy. For European Union (“EU”) or Swiss residents, in accordance with the applicable legislation, we have implemented safeguards to guarantee a suitable level of protection for any data transferred beyond your borders. These safeguards include us signing European Commission-type Contractual Clauses for the transfer of your data.

Data storage

Your personal data will be stored during your relationship with us or until you withdraw your consent. Once our relationship with you has terminated or you have exercised your right to have data deleted, your data will be stored, duly blocked, to the extent that it is necessary to the effects of the liability of the Company, available to law courts and tribunals, the Tax Authorities or the competent Public Authorities, for the requirements of the liability derived from the data processing for the period of prescription of these (in general, six years for accounting statements).

How we Protect the Personal Data

We have in place administrative, technical and physical safeguards designed to protect the personal data that users have provided to us against its destruction, loss, alteration, communication or accidental, legal or unauthorized use.

Enlaces a Otros Sitios Web y Plug Ins de Tercero

Our Site may contain links to other sites for the convenience and information for our users. These sites may be operated by other companies with no connections to us. As a rule, these linked sites have their own privacy policies or notices which we recommend you read carefully in the event that you visit any of these linked sites. We do not assume any liability regarding the content of web sites with no connection with us or for the use made of these sites or the privacy practices of these sites. The providers of plug-ins included in our Site such as for example social media plug-ins may use automatic resources to gather personal data on Site usage by the users and their interaction with these elements. Gathering this personal data

is subject to the privacy policies or notices of the providers of these plug-ins and not to this Online Privacy Notice. To the extent of that permitted by the applicable legislation, we assume no liability for the data protection practices of these providers.

Updates to our Online Privacy Notice

This Online Privacy Notice (and also its appendices) may be subject to regular updates with no prior notice to reflect the changes introduced to our personal data practises. When these involve major changes, we will notify you with a visible notice on our Site, indicating at the top of our Online Privacy Notice the date of the latest update and whenever legally applicable, we may request your consent once more.

How to Contact us

Users may contact us to update their data or exercise their rights in accordance with this Online Privacy Notice by sending an email to rpk@rpk.es or in writing to :

RPK, S.COOP. [F-01.009.554], Calle Portal de Gamarra, 34, 01013, Vitoria-Gasteiz (Álava).

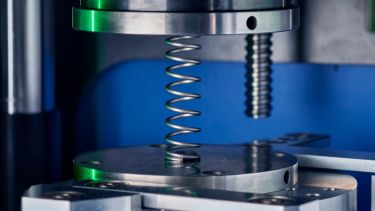

Compression Springs

Compression Springs