Beyond the spring catalog: the value of custom design

Standardization in docks limits performance in demanding sectors, where the lack of technical customization generates inefficiencies, cost overruns and functional failures.

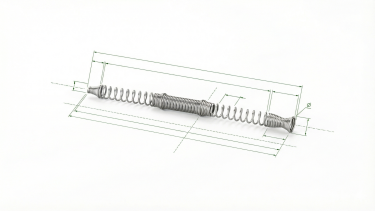

In the world of spring and metal component manufacturing, standardization has brought speed, but also limitations. Many manufacturers focus on producing large volumes from a fixed catalog of standard springs, overlooking the technical adaptability that many projects truly require.

The lack of technical customization: a silent obstacle

As a result, engineering and purchasing teams often face a familiar dilemma: they must adapt their design to the supplier’s catalog rather than finding a supplier who can adapt to their application’s needs.

In sectors such as automotive, medical, or e-mobility, where every micron can determine system performance, the lack of technical customization results in inefficiencies, additional costs, and even functional nonconformities.

Designing a spring is not just about defining a diameter or an elastic force. It also involves:

- Understanding material interaction with its environment

- Fatigue cycles

- Dimensional tolerances

- Behavior under dynamic or thermal loads

Without that level of collaborative engineering, a standard spring or component can quickly become a weak point in a high-performance system.

RPK Group: five decades of custom engineering

At RPK Group, we’ve been designing and manufacturing springs, stampings, bus bars, and complex metal components for over 50 years. We serve high-demand industries such as automotive, electrical, medical, and industrial, where every component must meet precise tolerances and performance criteria.

Our key difference is that we don’t offer a closed catalog, we provide a full co-design service with our customers. From the earliest stages of a project, our engineers collaborate to define the optimal geometry, material, heat treatment, and surface process.

This approach allows us to develop customized solutions that maximize component life, reduce the risk of premature failure, and optimize production costs.

At RPK Group, we believe that technical customization is not an extra service, it’s the core of high-level spring manufacturing.

The challenge of finding a true custom spring partner

The spring market is full of suppliers offering standard products. However, when a project requires critical specifications, few are willing to take on the challenge of developing a solution from scratch.

This design gap typically comes down to three main issues:

- Lack of in-house engineering expertise in calculation, materials, and simulation

- Rigid production setups optimized for standard, repetitive parts

- Poor technical communication between the supplier and the customer during the early development phases

The result is often the same: manufacturers deliver parts that are “similar” — but not “exactly what’s needed.” And in high-value sectors, that difference translates into deformations, force losses, or functional failures in the final assembly.

At RPK Group, we tackle this challenge from a different philosophy: every project is unique.

Our engineering teams use FEM simulation software, test benches, and high-precision metrology systems to predict spring behavior before production begins. This reduces iterations, shortens time-to-market, and ensures compliance from the first batch.

Why RPK Group is the ideal partner for custom springs

- Advanced application engineering: from conceptual design to final validation

- Functional co-design: combining analytical calculation, FEM simulation, and practical expertise to ensure performance

- ·Production flexibility: adaptable lines for prototypes, short runs, or large-scale series without compromising quality

- Metrological control and full traceability: micron-level measurements and complete lot tracking

- Cross-sector expertise: applying knowledge from automotive, medical, and e-mobility to new developments with a global perspective

Working with RPK Group means partnering with a team that understands both the physics behind every spring and the reality of industrial processes.

We don’t just deliver products — we provide solutions that work.

Technical customization as a competitive advantage

If your company is looking for a partner capable of designing and manufacturing custom springs or metal components, RPK Group can be your strategically.

We’ll study your application and develop a tailored solution that combines performance, durability, and reliability.

In an environment where standardization has become the norm, the ability to customize springs is what sets true leaders apart.

A well-designed spring doesn’t just perform its function, it improves system efficiency, reduces maintenance, and enhances product stability.

At RPK Group, every project starts with listening to the customer’s needs and ends with an optimized solution that delivers on its promise.

We design what others can’t.

We manufacture what others won’t.

At RPK Group, we turn custom engineering into measurable performance.